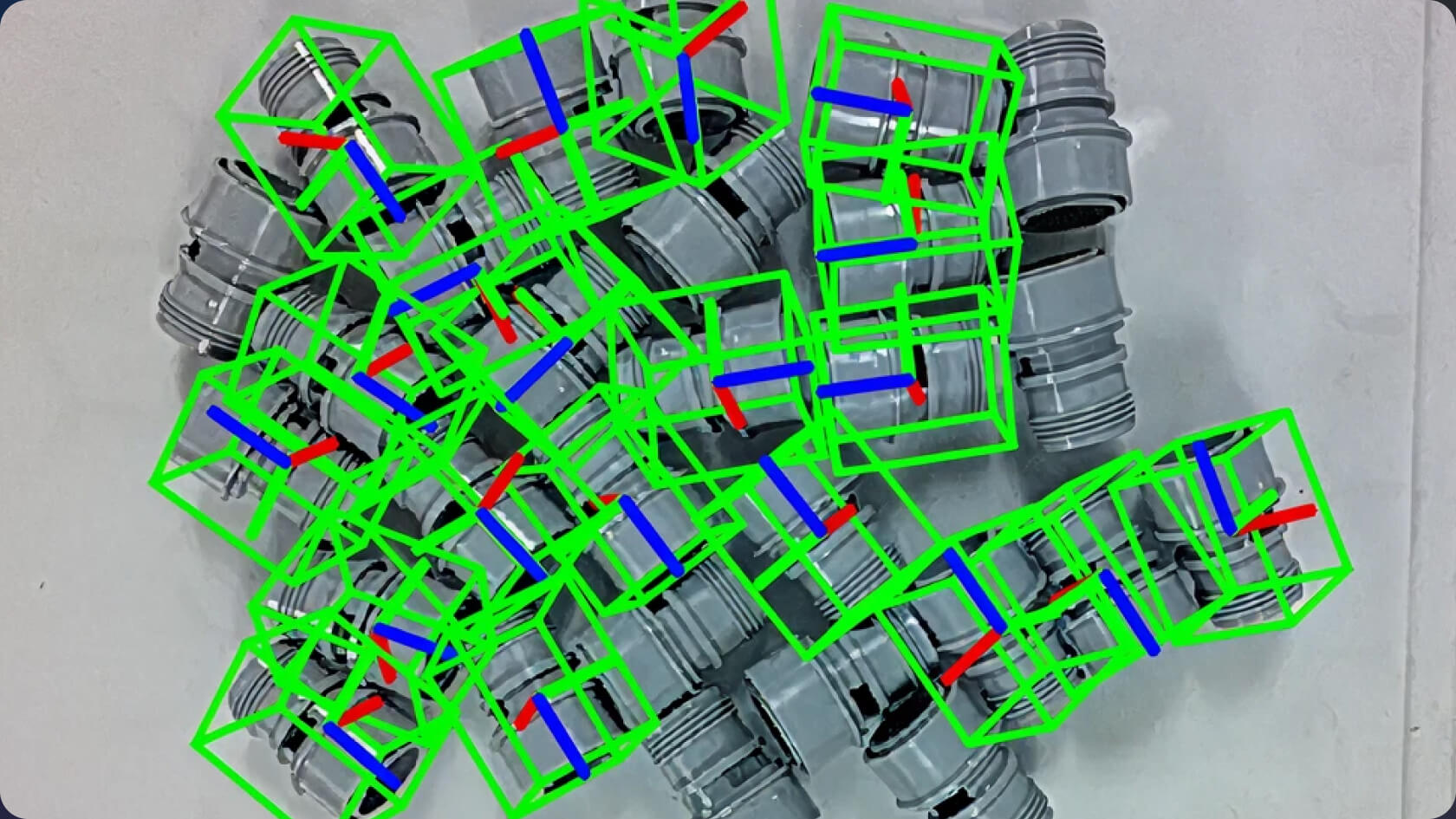

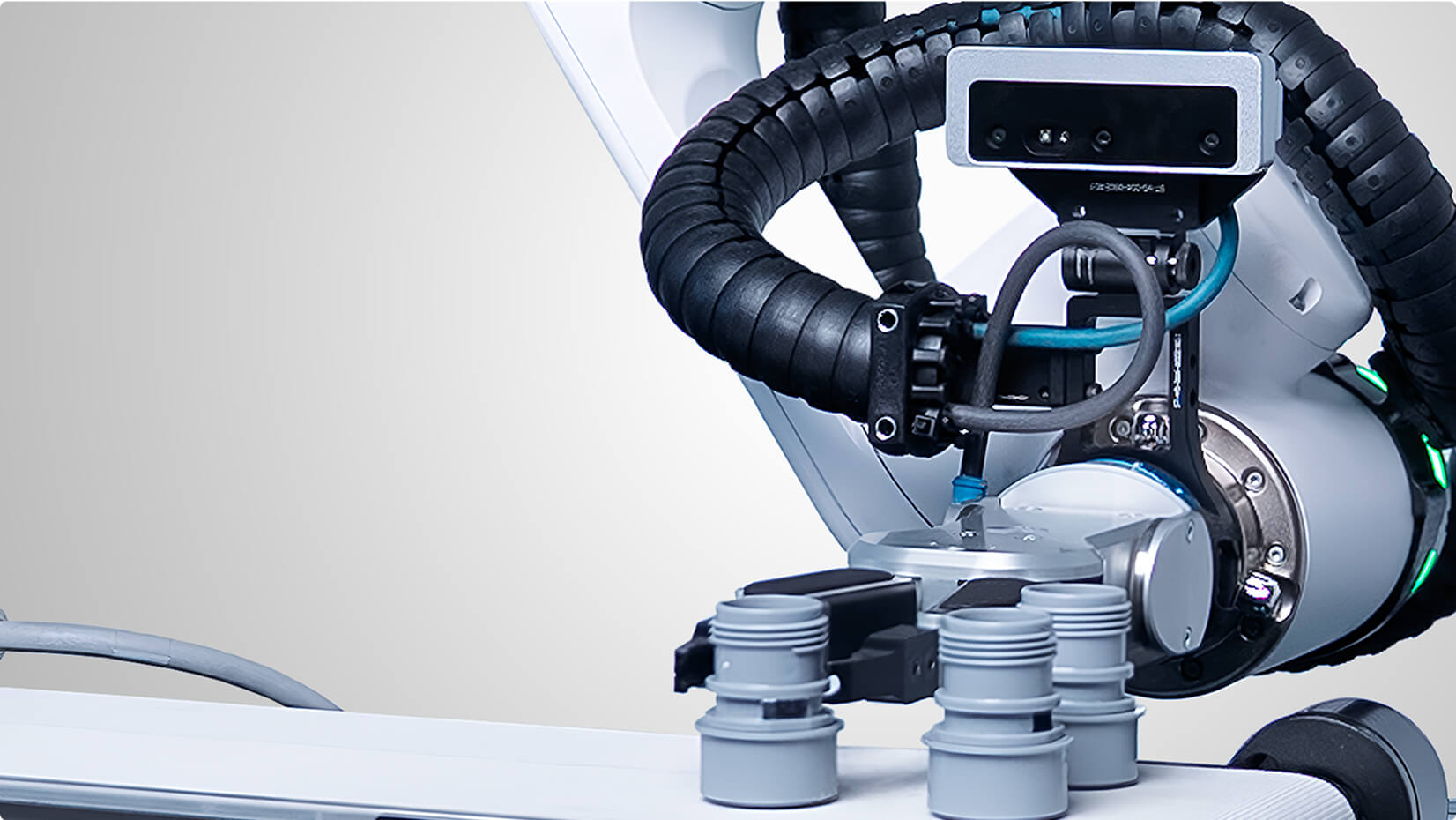

Vention integrates the Luxonis OAK‑D Pro PoE camera directly onto their robot arm as the perception module. The camera delivers high-resolution color imagery, global shutter stereo depth, and onboard neural inference all processed directly on-device. In the demo, the robot identifies and picks parts from a bin in real time, without prior calibration. The Luxonis camera provides the depth map and spatial features needed for the robot to understand object shape, position, and orientation. This enables accurate grasp planning and closed-loop control executed entirely on the edge, without relying on cloud compute or external calibration steps.